McElroy Metal Roofing

Build with excellence. McElroy Metal is one of the industry leading manufacturers of metal siding, metal roofing and substructural components. McElroy Metal offers a wide range of products suitable for projects of all sizes, from single family homes to industrial size commercial ventures. Our extensive line of products, combined with a strong contractor network, makes McElroy Metal Roofing Materials the perfect choice for your projects.

Standing Seam Panels by McElroy

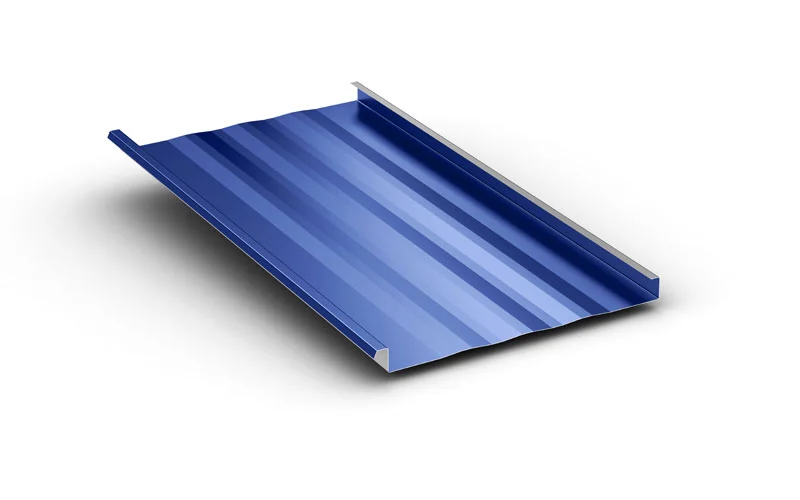

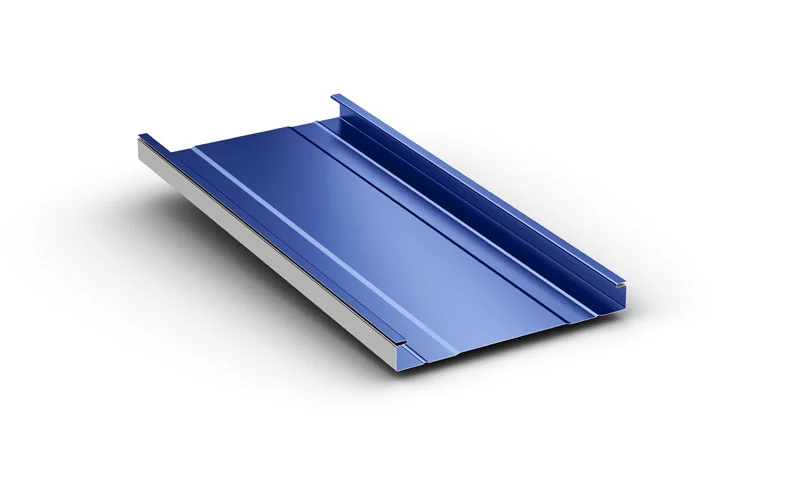

Maxima Roof Panels

McElroy offers three distinct Maxima profiles: Maxima, Maxima 1.5, and Maxima ADV, making it the industry's most extensive selection of vertical leg standing seam systems. Each profile provides unique performance characteristics, enabling users to match a Maxima panel to specific aesthetic and performance requirements, meeting the diverse needs of architects and contractors.

Additionally, McElroy factory technicians can produce Maxima panels on-site, providing convenient options for certain projects. Maxima 1.5" and 2" panels are also available in curved forms, suitable for radius roof applications.

All Maxima panels are mechanically seamed, and mechanical seamers and hand crimpers can be rented through Developmental Industries (DI) at mcelroyseamers.com, a dedicated website for McElroy Metal customers. Rental fees for each equipment type, along with relevant terms and conditions, can be found on the site. It's important to note that DI is the sole approved supplier for this equipment.

Furthermore, McElroy Metal offers factory eave notching on Maxima standing seam panels, providing added convenience and efficiency for installation.

Benefits & Specs

- Mechanically seamed

- Sealant: Factory applied (on non-curved panels only)

- 2" factory-formed eave notch (available upon request)

- For 1.5" panels: 1:12

- For 2" panels: 1/2:12

- For 3" panels: 1/4:12

Minimum Slope:

Installation:

- Can be installed over solid deck or open framing

Thermal Movement:

- Floating clips allow for 3 1/8" of movement

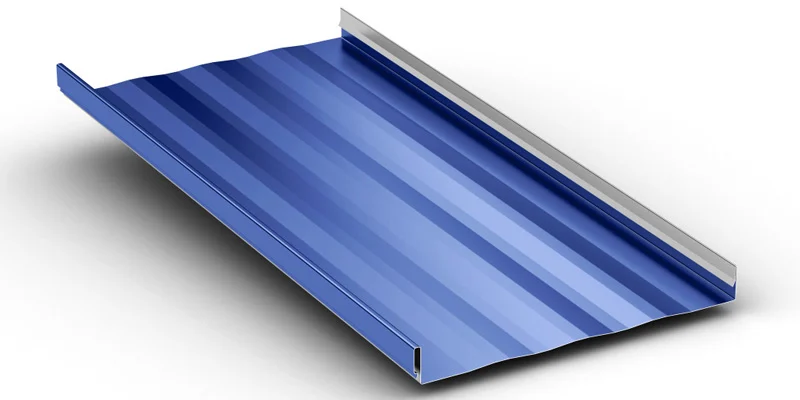

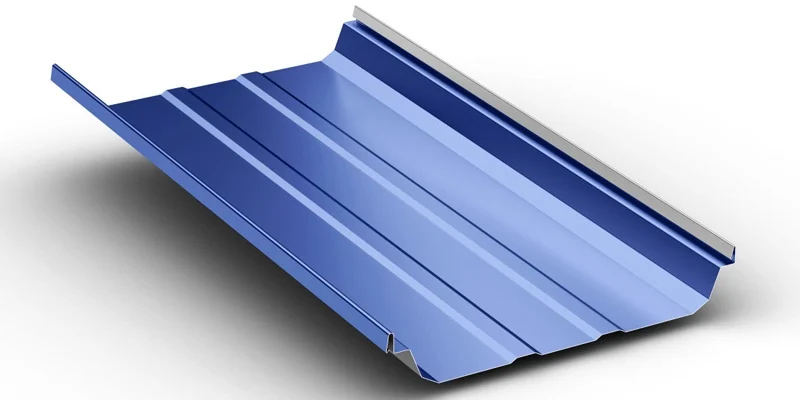

MedallionLok Roof Panels

Medallion-Lok offers the perfect blend of beauty and elegance, embodying the charm of a standing seam roof. With its narrow 1.75-inch tall standing seam, it adds a touch of curb appeal to any project, creating sharp and clean visual lines. Featuring hidden clips and a snap-together seam, Medallion-Lok eliminates the need for job site seaming, streamlining the installation process. Though primarily designed for commercial use, Medallion-Lok also serves as an excellent choice for larger, custom homes.

All Maxima panels are mechanically seamed, and mechanical seamers and hand crimpers can be rented through Developmental Industries (DI) McElroy Metal provides factory eave notching on Medallion-Lok standing seam panels, further enhancing convenience and efficiency during installation.

Benefits & Specs

- Minimum slope: 3:12

- Sealant: Factory applied

Installation:

Can be installed over solid deck or open framing

- Fire Rating: Class A

- Uplift Test: UL580 Class 90, ASTM E1592

- Air Infiltration: ASTM E1680

- Water Infiltration: ASTM E1646

- Class 4 Impact Resistance: UL 2218

- Florida State Approval: 1747.5 and 1832.7

- Fire Resistance: UL263

- Miami Dade Approval

- ICC-ES Approval: ESL-1082

- Panel Width: 12", 16", and 18"

Panel Configurations:

- Striated, Ribbed, or Flat Pan (Striated recommended)

Substrate:

- Standard 24 GA Galvalume®

- Optional 22 GA Galvalume

- Optional .032 aluminum

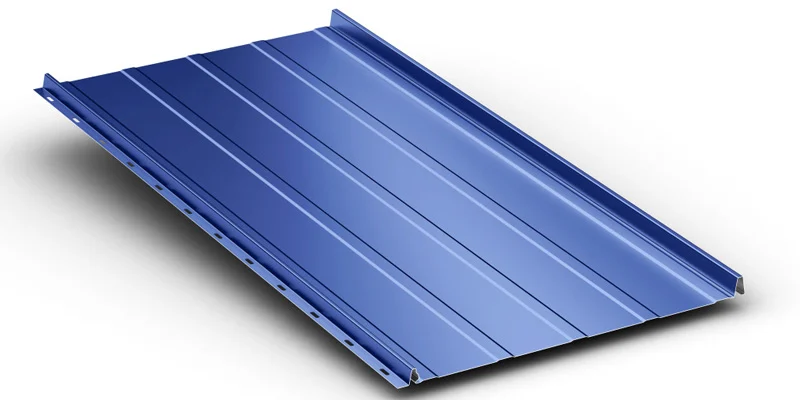

Meridian Panels

Meridian offers a complete package - an aesthetically pleasing, snap-together standing seam roof panel that is both cost-effective and straightforward to install. No clips are necessary, as Meridian panels are easily attached to the roof deck using pancake head fasteners. Whether for commercial or residential projects, Meridian proves to be an outstanding choice!

McElroy Metal provides factory eave notching on Meridian standing seam panels, adding convenience and efficiency to the installation process.

Benefits & Specs

Factory formed eave notch available upon request. Minimum slope: 3:12.

Installation:

- Must be over solid deck.

- Fire Rating: Class A.

- Air Infiltration: ASTM E1680.

- Water Infiltration: ASTM E1646.

- Class 4 Impact Resistance: UL 2218.

- Texas Department of Insurance Approval: Evaluation RC-34.

- Florida State Approval: 2358.1.

Panels Options:

- Panel width: 12" and 16".

- Panel configurations:

- 16" Minor Ribs or Striated.

- 12" Minor Ribs or Striated.

Substrate:

- Standard 26 GA Galvalume® (16" panels only).

- Standard 24 GA Galvalume (12" and 16" panels).

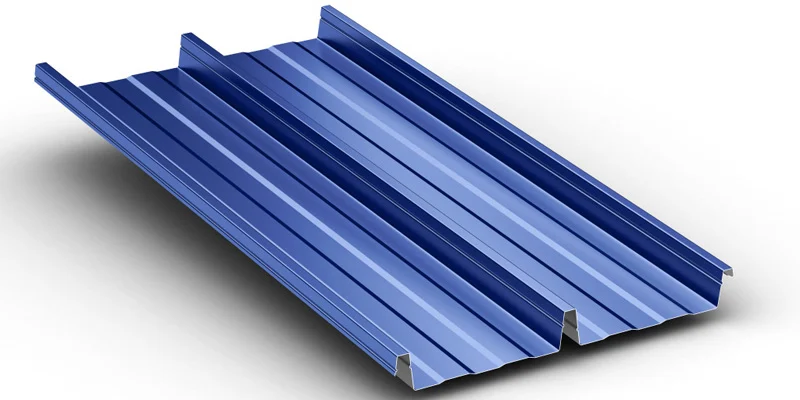

138 & 238 T Panel Options

Introducing a new standard in standing seam performance, the 138T and 238T panels boast technological advancements that surpass generations of traditional roofing systems. These symmetrical standing seam systems with mechanically seamed caps offer numerous advantages, including patented recover solutions that excel at reviving existing metal or shingle roofs.

The most notable advantage of the 238T and 138T systems is their ease of repair and alteration after installation. Unlike asymmetrical standing seam systems, individual panels of 138T and 238T can be effortlessly removed and replaced. This capability becomes crucial as Galvalume roof life expectancy reaches up to 60 years, ensuring lasting durability and convenience for maintenance and future modifications.

Benefits & Specs

- 138T Minimum slope: 2:12

- 238T Minimum slope: 1/2:12 (1/4:12 considered with prior approval)

Installation:

- 138T must be installed over solid deck

- 238T can be installed over solid deck or open framing

- Air Infiltration: ASTM E1680

- Water Infiltration: ASTM E1646

- Static Water: FM 4471 Appendix G, ASTM E2140

- Texas Department of Insurance: RC-270

- Florida State Approval: FBC #16606.1; #16606.2; #16606.3

- Miami Dade Approval

- CC-ES Approval: ESL-1082

- FM Class: 1-SH

Panel Options:

- Panel Height & Width:

- 138T: 1 3/8" x 12", 16", 18"

- 238T: 2 3/8" x 16", 18", 24"

- 238T: 24" Panel formed on-site only

Panel Configurations:

- 138T (16" & 18"): Flat, Striated, Plank & Pencil Ribs, Plank, Minor ribs (Plank & Pencil Rib recommended)

- 138T (12"): Flat, Striated, Minor Ribs, Plank (Plank recommended)

- 238T: Flat (16" & 18" only), Striated, Plank & Pencil Ribs, Plank, Minor Ribs (Plank & Pencil Rib recommended)

Substrate:

- Standard 24 GA Galvalume®

- Optional 22 GA Galvalume

- Optional .032 and .040 aluminum

- Optional 16 oz and 20 oz copper (Houston Plant Only)

MasterLok-90 & MasterLok-FS

MasterLok-90 (or ML-90) embodies a snap-together trapezoidal standing seam system, while MasterLok-FS (or ML-FS) features a mechanically seamed trapezoidal design. Both systems are tailored for projects encompassing slopes as minimal as 1/4:12.

MasterLok-FS, also known as ML-FS, similarly showcases a mechanically seamed trapezoidal standing seam system, catering to projects with slopes as low as 1/4:12.

Benefits & Specs

Details:

- Sealant: Factory applied to improve weather-tightness.

- Minimum slope:

- ML-90: 1/4:12

- ML-FS: 1/4:12

Can be over solid deck or open framing

MasterLok-FS:

- Mechanically seamed system.

MasterLok-90:

- Snap Together System.

- Fire Rating: Class A.

- Uplift Test: UL580 Class 90, ASTM E1592.

- Air Infiltration: ASTM E1680.

- Water Infiltration: ASTM E1646.

- Class 4 Impact Resistance: UL2218.

- MasterLok-90 Florida State Approval: 1832.2, 1747.1.

- MasterLok-FS Florida State Approval: 8051.1.

Panels Options:

- Panel Width: 24".

Substrate:

- Standard 24 GA Galvalume®.

- Optional 22 GA Galvalume.

Mirage II Panels

Mirage II is a snap-together roofing panel with concealed fasteners, boasting 8" on-center ribs. This remarkable panel showcases a 1 3/4 inches high seam and is compatible with installation over solid decking or substructural members. For slopes below 3:12, factory-applied sealant is essential, although Mirage II is versatile enough to be installed on slopes as low as 1/4:12. This panel finds its primary application in the mini-storage industry, catering to projects that demand shorter length panels and specialized contractor details for effective use in lower slope applications.

Benefits & Specs

Installation:

- Can be installed over solid deck or open framing.

Fire Rating:

- UL790 Class A

- Uplift Test: UL580 Class 90

- Impact: UL 2218 Class 4

Panel Options:

- Panel Width: 16".

- Panel Configurations: Ribbed.

Coating:

- Kynar 500® (PVDF).

Substrate:

- Standard 24 GA Galvalume®.

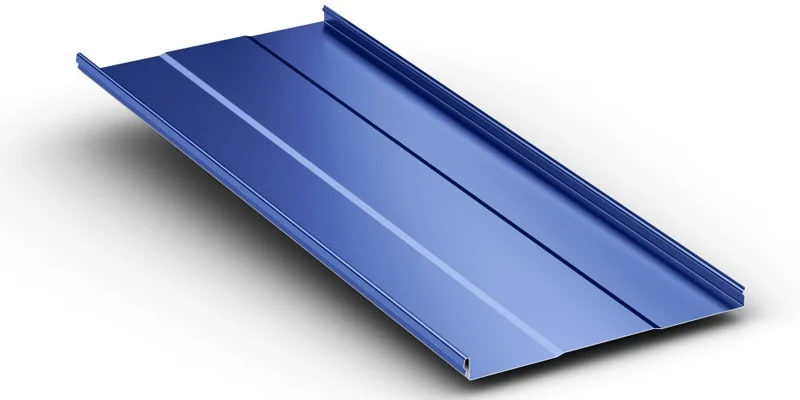

InstaLoc Snap Lock Panels

Instaloc is a snap-together standing seam system with a 1" seam, installed using concealed clips. This system is specifically designed for use with solid decking, making it an excellent choice for light commercial and residential applications. The low profile seam adds to its appeal and versatility.

Benefits & Specs

- Minimum Slope: 3:12

- Installation: Must be over solid deck

- Sealant: Factory applied

- Manufacturing Facility: Houston, TX

- Note: Oil Canning is a natural occurrence in metal panels and is not a cause for panel rejection

Testing:

- Fire Rating: Class A

- Uplift Test: UL 580 Class 90, UL 1897

- Class 4 Impact Resistance: UL 2218

- Texas Department of Insurance Approval: RC-86

Panel Options:

- Panel Height & Width: 13"

- Panel Configurations: Striated, Plank, and Minor Rib (Striated recommended)

Coating:

- Kynar 500® (PVDF)

Substrate:

- Standard 24 GA Galvalume®

No matter what type of metal roof panels you are looking for, McElroy metal materials have got you covered. Learn more about your metal options with Alpine Sheet Metal Systems. We will work with you to discover your needs and provide real options for your metal project. Call Alpine Sheet Metal Systems today to get your project started.